Double-end large-diameter feeding, fast and uniform feeding; filter plate components are opened and closed in groups, automatic unloading, and the return time is short.

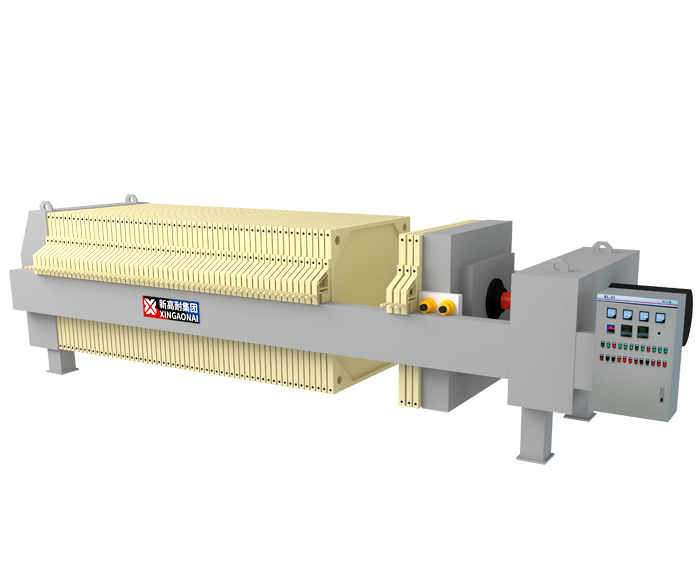

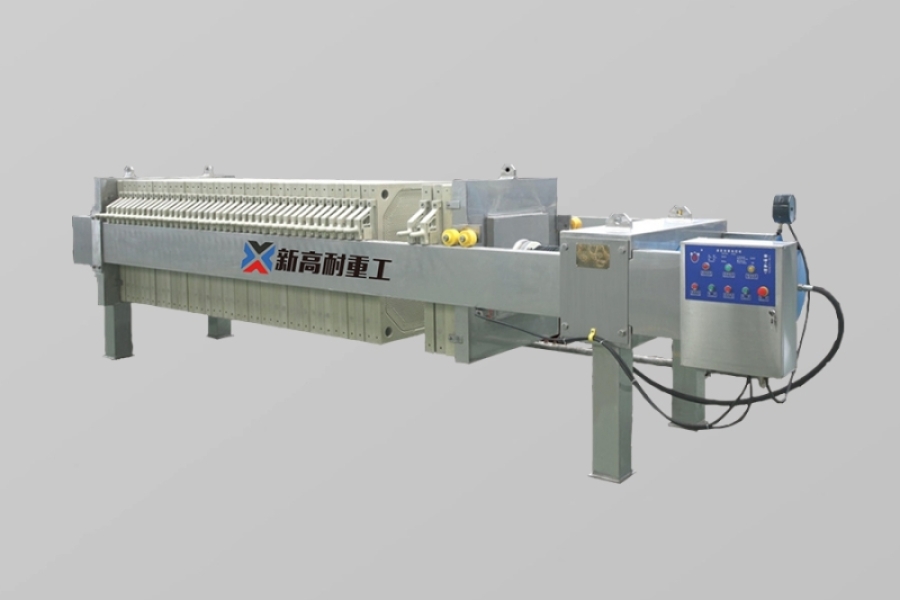

The plate and frame filter press is a fully automatic filter press equipment newly developed by our group with fast feeding and fast pulling plate unloading,it is suitable for operations that require solid-liquid separation, especially for users with high requirements for processing capacity and filtration accuracy.

Double-end large-diameter feeding, fast and uniform feeding; filter plate components are opened and closed in groups, automatic unloading, and the return time is short.

The working cycle per hour is more than 6, the output of a single machine is increased by 1-1.5 times, and the performance is much higher than that of ordinary filter presses.

Equipped with a program automatic control system, it can automatically control each process of the filter press and reduce manual operations.

The embedded diaphragm squeezes the filter cake to achieve the moisture content of the filter cake <6%, and the moisture content of the mineral filter cake is about 18%.

The opening speed, pulling force, the number of feeding ports, and the discharging gap can all be adjusted, and the normal service life can reach more than 50,000 times.

Working principle: using the pressure difference on both sides of the filter cloth, most of the water in the material is forced to pass through the filter cloth and flow out of the body, while the material is blocked in the filter chamber to form a filter cake to achieve the purpose of filtration.

| Model | Filter area (㎡) | Filter plate specification (mm) | Number of filter plates | Filter pressure (mpa) | Power (kw) | Pull-plate motor power (kw) |

|---|---|---|---|---|---|---|

| XMZ250/1250 | 250 | 1250*1250*65 | 91 | 1.0 | 5.5 | 0.75 |

| XMZ500/1500 | 500 | 1500*1500*75 | 123 | 1.0 | 11 | 1.5 |

| XMZ800/2000 | 800 | 2000*2000*85 | 107 | 1.0 | 15 | 1.5 |

specialized in R&D and manufacturing of crushing, milling, screening, feeding, conveying, automation and other equipment.