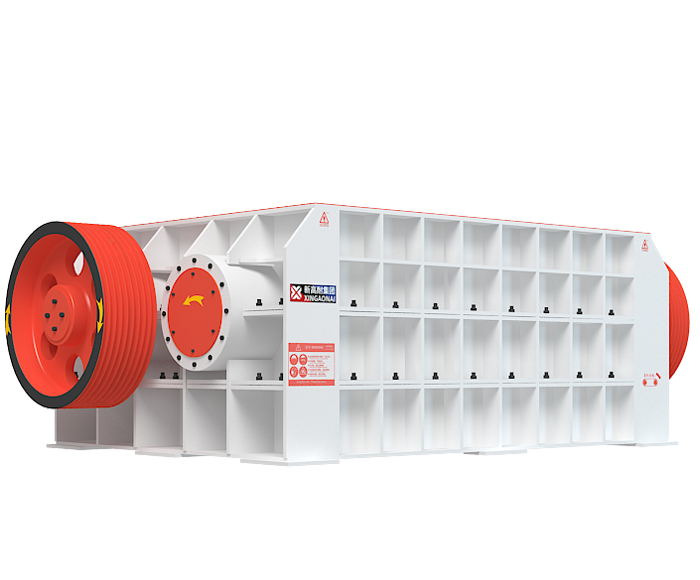

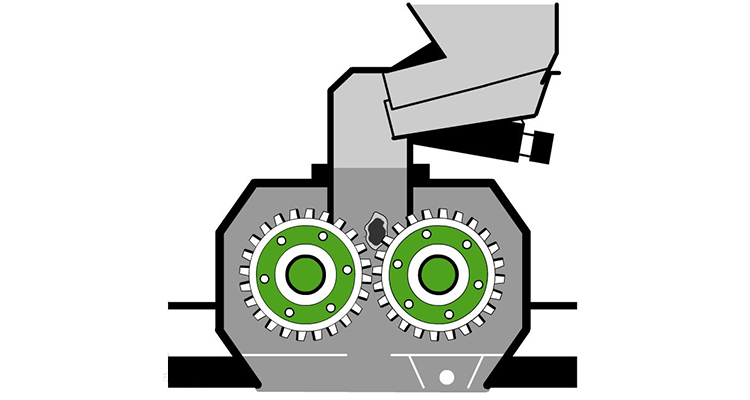

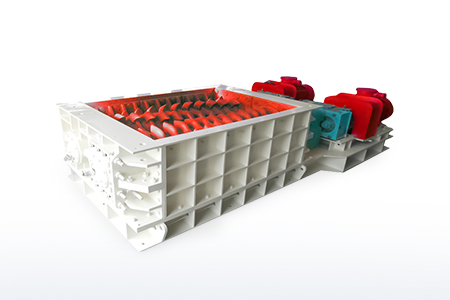

Broken teeth are cast with Bashi grinding alloy, the casting and thermal external process are advanced, with high strength, toughness and abrasion resistance. The service life is 2-3 times that of the industry's general high manganese steel and alloy steel; two sets of independent driving devices, the two broken rollers can work independently, and in actual production, the working system can be changed according to the amount of feeding, use stand -alone work when the feed is small, dual -machine work when the feed is big, high energy saving efficiency.