Self-aligning double-row radial spherical roller bearings are adopted, which has low running resistance, remarkable energy-saving effect, and can be used both dry and wet.

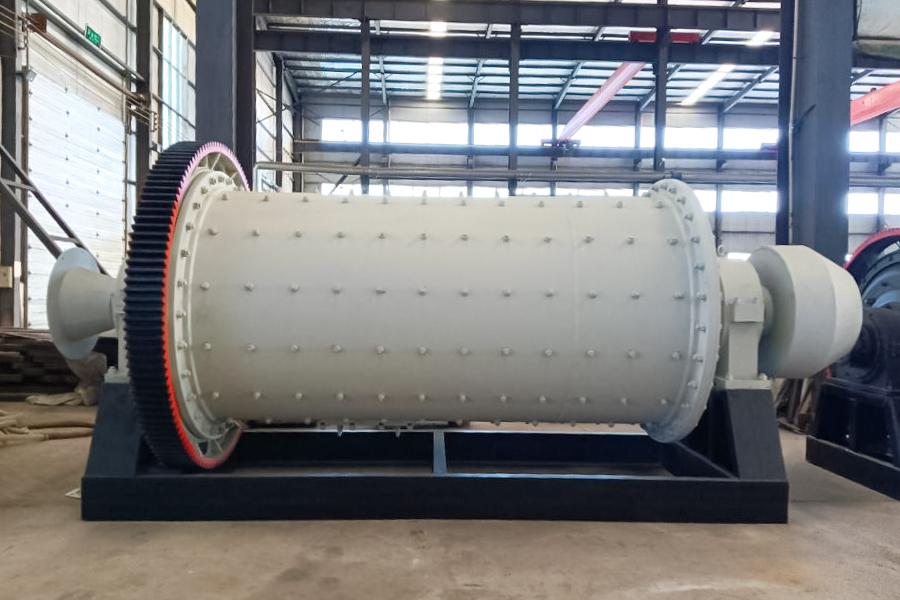

Ball mill is one of the high-fine grinding machines widely used in the metal ore crushing and grinding industry. It is the key equipment for crushing materials after crushing. It is suitable for grinding various hard materials in the mineral processing industry and is an important powder in the mineral processing industry. grinding equipment.

Self-aligning double-row radial spherical roller bearings are adopted, which has low running resistance, remarkable energy-saving effect, and can be used both dry and wet.

End cover structure, large diameter inlet and outlet, large processing capacity; reasonable steel ball gradation, good crushing effect.

The wearing parts are all cast with high-quality materials, and the casting process is first-class, which has good wear resistance and effectively reduces the cost of use.

Separate installation, simple and easy to operate; there is no inertial impact in the crushing process, and the equipment runs smoothly.

The material is uniformly entered the grinding machine's first warehouse by the air -in -the -axis spiral through the material, different specifications of steel balls in the interior, the cylinder rotation generates centrifugal force to bring the steel ball to a certain height, which has a attack and grinding effect on the material, after the material reaches rough grinding in the first warehouse, it enters the second warehouse through the single -layer compartment board,the warehouse is inlaid with a flat lining plate with steel ball inside, further grind the material, and the powder is discharged through the unloading plate to complete the powder grinding operation.

specialized in R&D and manufacturing of crushing, milling, screening, feeding, conveying, automation and other equipment.