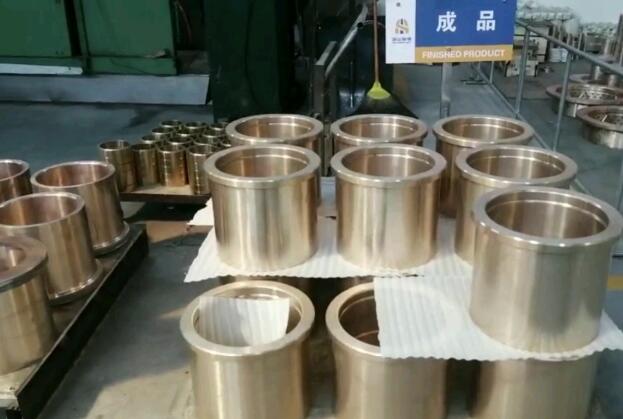

As a common material for mechanical parts, the main function of copper sleeve is to reduce wear and reduce friction during friction. The copper sleeve of cone crusher is under great pressure and wear when the machine is working. If the material of copper sleeve is improperly selected, the hardness or strength is insufficient, the service life of copper sleeve will be affected. Lack of lubrication on the friction surface of copper sleeve or poor lubrication conditions will lead to aggravated wear of copper sleeve. In the operation of mechanical equipment, unreasonable operation methods or frequent stopping and starting will cause wear on copper sleeve.

Grinding with oilstone

First, you need to remove the copper sleeve, and then use oilstone to grind the copper sleeve. The technique should be gentle to avoid secondary wear or other negative effects caused by excessive friction. When grinding, pay special attention to the worn parts to avoid excessive wear, so as to ensure the service life of copper sleeve. When selecting copper sleeve materials, the corresponding materials should be selected according to the specific use scenarios. For example, high-temperature alloy materials can be selected for use in high-temperature scenarios; in addition, you also need to pay attention to indicators such as hardness and strength of the material. When using the oilstone, you can apply engine oil or other lubricants to better protect the copper sleeve and avoid damaging it. After grinding, put the copper sleeve on and test run it for a certain period of time to check whether it meets the requirements.

Replace the copper sleeve of the cone machine

If the working requirements cannot be met after grinding, and the copper sleeve is excessively worn, the copper sleeve of the cone machine needs to be replaced. When replacing, you need to pay attention to the size, material and other factors of the copper sleeve to avoid improper installation and cause greater problems. After replacement, the machine should be re-debugged to ensure good use effect.

Before using the machine, you should first inspect and maintain the machine, especially to ensure that the machine is well lubricated, which can slow down the wear of the copper sleeve. Clean and maintain the copper sleeve of the cone machine regularly to extend the life and use effect of the machine. You can use professional maintenance fluids regularly to clean it to avoid other impurities and corrosive substances adhering to the copper sleeve.

In short, the copper sleeve of the cone machine is an important part of the equipment, and wear is a normal phenomenon, but it needs to be inspected and maintained in time, especially in terms of lubrication, in order to reduce the wear of the copper sleeve and better use. Improper grinding and replacement of the copper sleeve will cause great damage to the machine, so it is necessary to strictly follow the operating requirements. When the equipment has abnormal problems, it must be repaired and maintained in time to ensure the safety and stability of the long-term operation of the equipment.

Article Title: Causes of wear and maintenance of cone crusher copper sleeve

Author:Xingaonai

Reprint URL: https://www.cadana.cn/industral-news/Causes-of-wear-and-maintenance-of-cone-crusher-copper-sleeve.html

specialized in R&D and manufacturing of crushing, milling, screening, feeding, conveying, automation and other equipment.