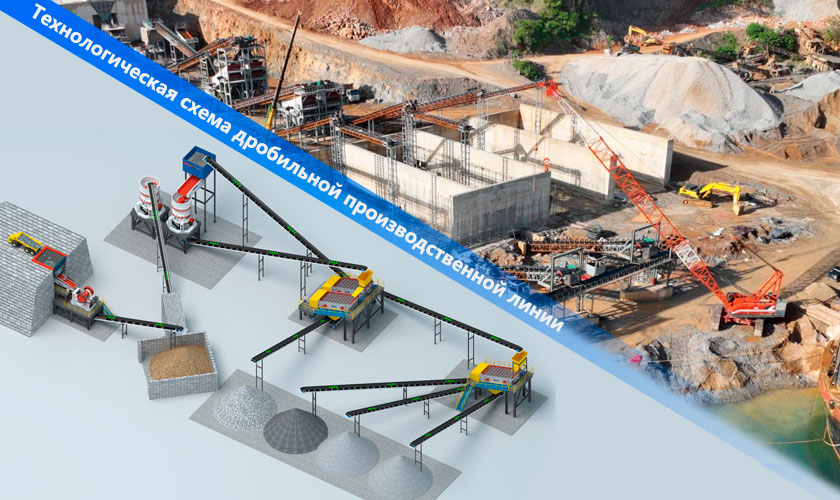

The stone crushing plant production line is a production line composed of various types of equipment for crushing materials. It is a combination of special equipment used to produce industrial building materials such as sand and gravel, stone crushing, etc. It is mainly composed of vibrating feeders, crushers (jaw crusher, impact crusher, cone crusher, hammer crusher, etc.), vibrating screens, conveyor belts and other equipment. The stone crushing plant production line has a high degree of automation, high crushing rate, energy saving and environmental protection, large output, and the produced stones have uniform particle size and good particle shape, which is suitable for the construction of various large, medium and small engineering projects such as highway bridges.

The vibrating feeder evenly transports the stone to the crusher for preliminary crushing. The coarse material produced is then sent to the impact crusher by the conveyor for secondary crushing. The crushed fine material is then screened out by the vibrating screen to separate different types of stones. The stone that does not meet the particle size requirements is returned to the impact crusher for re-crushing, and the crushing operation is completed over and over again.

The crushing production line composed of Xingaonai Heavy Industry equipment has a large crushing ratio, can process in batches, and has a high output, which brings considerable economic benefits to customers. In addition, the equipment is easy to maintain and service, and the wearing parts are made of the latest domestic high-strength wear-resistant materials, with low loss and long service life, saving customers a lot of maintenance costs.

Generally speaking, a stone crushing plant production line with an output of less than 100 tons per hour is a small stone crushing plant; a medium-sized stone crushing plant with an output between 100-400 tons per hour is called a large stone crushing plant; and a large stone crushing plant with an output of more than 400 tons per hour is called a large stone crushing plant. The configuration of each stone crushing plant production line is different, and the following examples will explain it in detail.

Production capacity: 550t/h

Crushing material: basalt

Feed size: ≤700mm

Equipment configuration: raw material warehouse, ZGCW1428 vibrating feeder, PE1200*1500 jaw crusher, 1 XGP300 single-cylinder cone crusher, 1 XHP300 multi-cylinder hydraulic cone crusher, 2 3YKQ3080 vibrating screens, several conveyor belts

Customer feedback: The entire production line was configured under the advice of the product manager of New Gaonai, taking into account my production needs and on-site inspections and the actual situation. The equipment configuration is efficient and reasonable, the overall operation is stable, and the failure rate is low. It helped me earn back the initial investment in just 3 months.

Production capacity: 280t/h

Crushed material: calcite

Finished product specifications: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Equipment configuration: ZGCW1528 vibrating feeder, PE750*1060 jaw crusher, PF1315 impact crusher, 4 2YKZ2460 vibrating screens, 2 iron removers

Design principle: Calcite is a stone with a relatively low hardness, so the impact crusher mainly based on impact crushing is selected, which is easier to control the particle size and particle shape of the output. The entire production line runs smoothly with a very low failure rate.

Production capacity: 80t/h

Crushed material: bluestone

Equipment configuration: raw material warehouse, ZGCW0928 vibrating feeder, XGN-Q0808 hammer crusher, 3YKQ1545 vibrating screen, several conveyors

Configuration evaluation: The advantage of hammer crusher is that it can be directly formed after one crushing without secondary crushing. One hammer crusher is equivalent to the crushing effect of two jaw crushers and impact crushers. It is very friendly to the production line of small stone crushing plant, with low initial investment cost and low failure rate in the later stage.

The above is a detailed introduction to the production line of stone crushing plant. If you want to know more about stone crushing plant or stone crushing plant equipment price, you can contact us by phone: +8617761642222 or email: sales@xgnchina.com. New Gaonai Heavy Industry looks forward to your visit to our factory. We will reimburse everything for pick-up and delivery. It is our purpose to establish a business with precision to meet customer needs and provide quality services with sincerity.

Article Title: Detailed explanation of stone crushing plant production line

Author:Xingaonai

Reprint URL: https://www.cadana.cn/industral-news/Detailed-explanation-of-stone-crushing-plant-production-line.html

specialized in R&D and manufacturing of crushing, milling, screening, feeding, conveying, automation and other equipment.