The bearing of the impact crusher is one of the core parts of the impact crusher. Its main function is to bear the weight of the impact plate and the rotor, and to support and reduce friction when rotating at high speed. If the bearing fails, it will have a significant impact on the working efficiency and quality of the impact crusher, so it is very important to repair it in time.

(1. Quality problems: The main bearing of the impact crusher is the core component of the rotation of the impact plate. If there are quality problems in the material, process, manufacturing, etc., the main bearing will be damaged.

(2. Improper use: When the impact crusher is used, if it is not used in accordance with the correct operating regulations, such as overload, long-term continuous operation, uneven loading, etc., it will cause varying degrees of damage to the main bearing.

(3. Bearing overheating: Bearing overheating is one of the common bearing failures. The main reason is poor lubrication or excessive bearing force. The solution is to stop the machine to check the bearing lubrication, replace the grease if necessary, and check whether the gap of the impact plate is too large and whether the bolts are loose.

(4. Environmental factors: It is inevitable that the impact crusher will be affected by environmental factors during use. For example, dust, particles, moisture, temperature, etc. Factors will cause damage to the main bearing.

(1. Improve quality: Impact crusher manufacturers and users should pay attention to product quality and choose impact crushers with excellent materials, exquisite workmanship and strict manufacturing.

(2. Correct use: When using the impact crusher, users should use the equipment in accordance with the prescribed operating methods, be careful not to overload it, and avoid long-term continuous operation.

(3. Regular maintenance: During the use of the impact crusher, regular maintenance should be carried out to ensure the normal operation of the equipment in terms of lubrication, cleaning, adjustment, etc., especially the lubrication and maintenance of the main bearing should be paid special attention.

(4. Improve the environment: When using the impact crusher, the impact of environmental factors on the equipment should be minimized. For example, a protective cover can be installed around the equipment to prevent dust and other substances from entering the equipment.

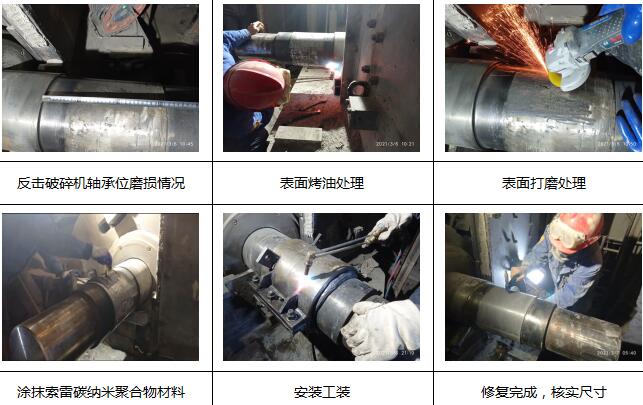

(1. Prepare tools and materials: wrench, hammer, grease, bearings, locating pins, etc.

(2. Shut down and cut off power: When the machine is shut down, cut off the power to ensure safety.

(3. Disassemble the bearing: Unfasten the accessories, take out the bearing, and clean it.

(4. Add grease and replace new bearings: Apply grease to the bearing and disk, install new bearings, and replace accessories such as locating pins at the same time.

(5. Check the bearing: reinstall the impact plate, conduct a trial run, and check whether the bearing runs smoothly.

(1. Regular inspection: It is recommended that users regularly inspect the impact crusher equipment, especially pay attention to the lubrication of the main bearing and add lubricating oil in time.

(2. Regular replacement: After the main bearing of the impact crusher has been used for a certain period of time, it should be replaced in time according to the use of the equipment to avoid safety accidents such as breakage.

(3. Cleaning and maintenance: During the use of the impact crusher, the equipment should be kept clean and hygienic, especially the main bearing and surrounding parts, which should be cleaned regularly.

(4. Avoid overloading: When using the impact crusher, overloading should be avoided to avoid unnecessary damage to the equipment.

In short, there are many reasons for the damage of the main bearing of the impact crusher, which is crucial to the normal operation of the impact crusher. However, as long as the maintenance of the equipment is strengthened, the equipment is used correctly, and corresponding solutions are taken, the service life of the equipment can be extended and the working efficiency of the equipment can be improved. New Gaonai Heavy Industry introduces the failure and maintenance methods of bearings, as well as some maintenance solutions, hoping to provide certain reference value for users.

Article Title: Causes and solutions for damage to the main bearing of the impact crusher

Author:Xingaonai

Reprint URL: https://www.cadana.cn/industral-news/Impact-crusher-main-bearing-damage.html

specialized in R&D and manufacturing of crushing, milling, screening, feeding, conveying, automation and other equipment.