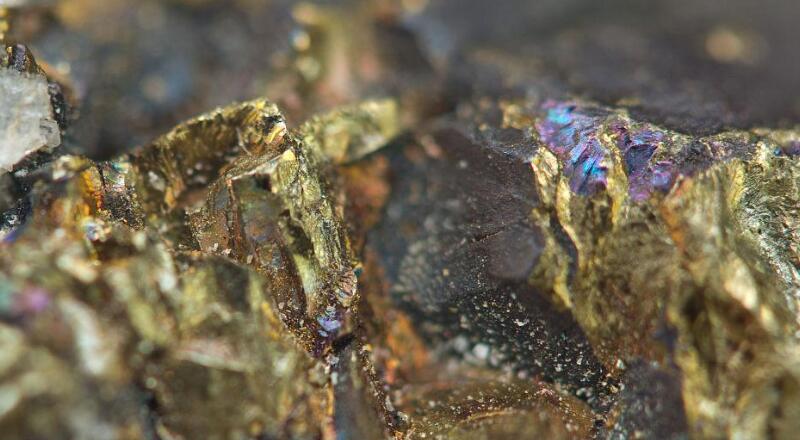

Extracting copper from chalcopyrite (CuFeS₂) usually involves the following steps:

Mining: Chalcopyrite ore is obtained through open-pit or underground mining.

Crushing: The ore is broken into small pieces.

Grinding: Further grinding into fine powder for subsequent processing.

Floatation: Utilizing the difference in the surface properties of minerals, chalcopyrite is separated from other minerals by flotation to obtain copper concentrate.

Roasting: The copper concentrate is roasted at high temperature to remove some sulfur and impurities to produce roasted sand.

Smelting: The roasted sand reacts with flux in the furnace to produce matte (Cu₂S-FeS) and slag, and the slag is separated.

Converter blowing: Air is blown into the matte in the converter to oxidize iron and sulfur to produce blister copper (about 98% purity).

Pyrometallurgical refining: The blister copper is further refined in a reverberatory furnace to remove residual impurities and produce anode copper.

Electrolytic refining: Anode copper is electrolyzed in an electrolytic cell to obtain high-purity cathode copper (99.99%).

The main steps to extract copper from chalcopyrite include mining, crushing and grinding, flotation, smelting (roasting, smelting, converter refining) and refining (fire refining, electrolytic refining), and finally obtaining high-purity copper.

Article Title: How is copper extracted from chalcopyrite

Author:Xingaonai

Reprint URL: https://www.cadana.cn/industral-news/how-is-copper-extracted-from-chalcopyrite.html

specialized in R&D and manufacturing of crushing, milling, screening, feeding, conveying, automation and other equipment.