In industrial production, impact crusher is a common crushing equipment, widely used in various ore crushing, railways, highways, energy, cement, chemical industry, construction and other industries. During the operation of the impact crusher, various adverse factors may cause the machine to malfunction. If a malfunction occurs, it must be promptly eliminated and repaired. Below, New High-Resistance Heavy Industry will mainly introduce the solutions to common faults of the impact crusher.

1. The bearing temperature is too high: There are many reasons for the excessive temperature rise of the bearing. Here we must first check whether it is because the lubricating oil has become less or deteriorated. If the bearing is short of oil, it is necessary to add oil in time, and the amount of lubricating oil added should be appropriate. Due to excessive or insufficient grease; grease contamination occurs, and the grease is replaced after cleaning the bearing. If the bearing is damaged, the bearing should be replaced in time. The bearing gland is too tight, and the bolts should be adjusted to a moderate tightness.

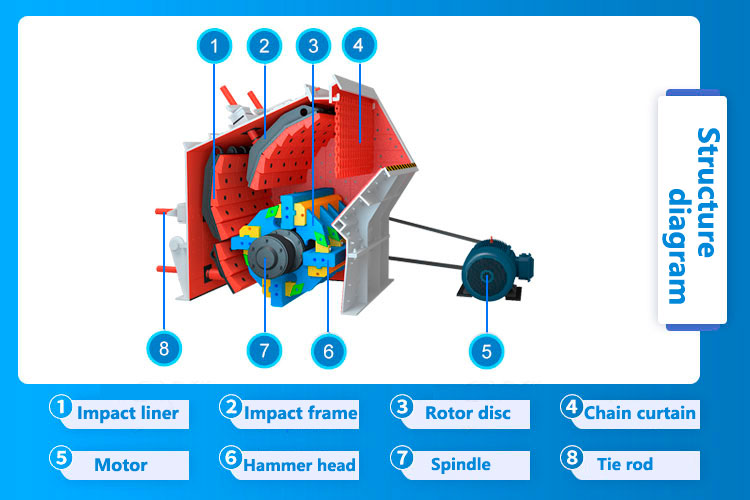

2. Abnormal vibration: The feed material of the impact crusher is too large, resulting in uneven wear. Check whether the impact plate, hammer head, etc. need to be replaced. When replacing or assembling the plate hammer, the rotor is not calibrated and balanced. Reinstall the plate hammer and balance the rotor. If the foundation is improperly treated, check the anchor bolts and reinforce them.

3. Excessive discharge particle size: This indicates that the plate hammer or the impact liner of the impact crusher is worn too much; check whether the gap between the hammer head and the impact plate is too large, generally 15-20mm is appropriate; or adjust the position of the impact frame so that its two sides and the frame lining can reach a relative gap to ensure the discharge particle size.

4. Leakage at the feed port: The feed port of the impact crusher has a certain inclination angle and a steep slope, which is easy to leak during the material transportation process. The solution is to install a feed guide device or a feed baffle so that the material can smoothly pass through the feed port into the crushing chamber.

5. Severe knocking sound: When there is a violent metal knocking sound in the machine, the power should be turned off immediately, and check whether there is any material that cannot be crushed into the impact crusher, stop the machine and clean the crushing chamber. If the parts in the machine fall off, they should be cleaned and tightened in time. It is recommended to regularly check the various parts of the equipment, such as the sealing of the lining plate, the machine casing, and whether the screws at the connection of each device are loose, and do a good job of daily maintenance and maintenance of the equipment.

6. A lot of dust: In order to solve the problem of a large amount of dust during work, users can equip additional dust removal equipment or add a closed cover when using it. They can also add a small amount of water to wet the material before entering the feed port of the impact crusher, or directly add a dust removal humidifier to cooperate with the work.

7. Belt flip: Due to belt damage, the V-belt needs to be replaced, and attention should be paid to the quality of the V-belt itself. Or because of the problem of pulley assembly, the active and driven pulleys need to be adjusted to the same plane.

The above are the common faults and solutions of Xin Gaonai Heavy Industry in the work of the impact crusher. When a fault occurs in production, I hope to help everyone solve it as soon as possible and reduce the impact on production.

Article Title: Common Faults and Solutions of Impact Crusher

Author:Xingaonai

Reprint URL: https://www.cadana.cn/industral-news/Common-Faults-and-Solutions-of-Impact-Crusher.html

specialized in R&D and manufacturing of crushing, milling, screening, feeding, conveying, automation and other equipment.